The battery industry

is on with silicon

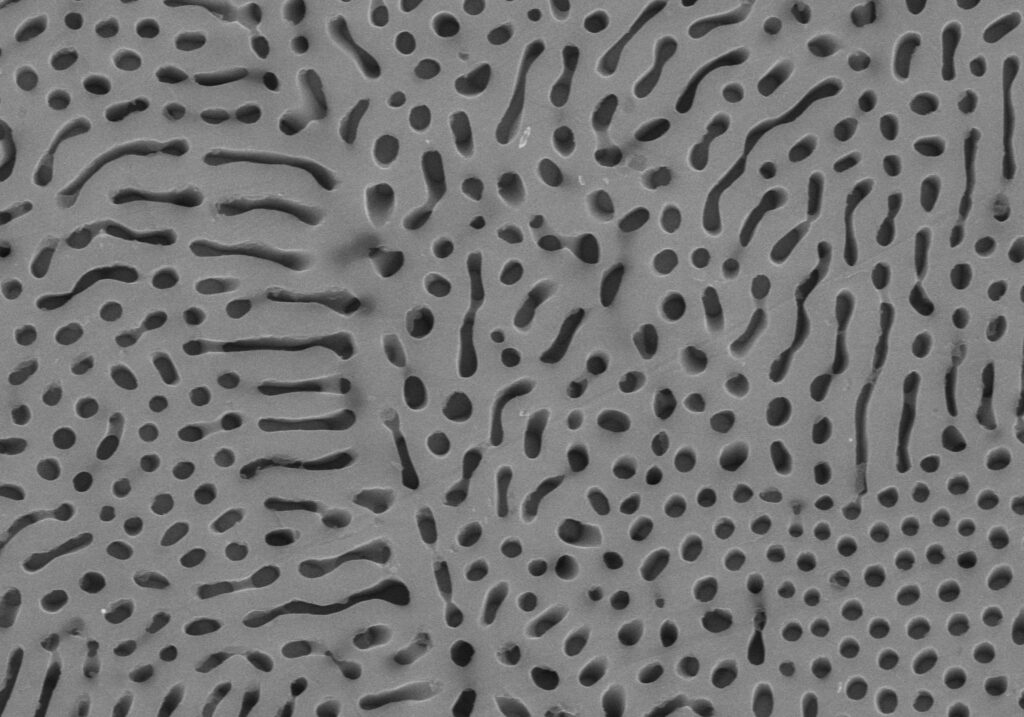

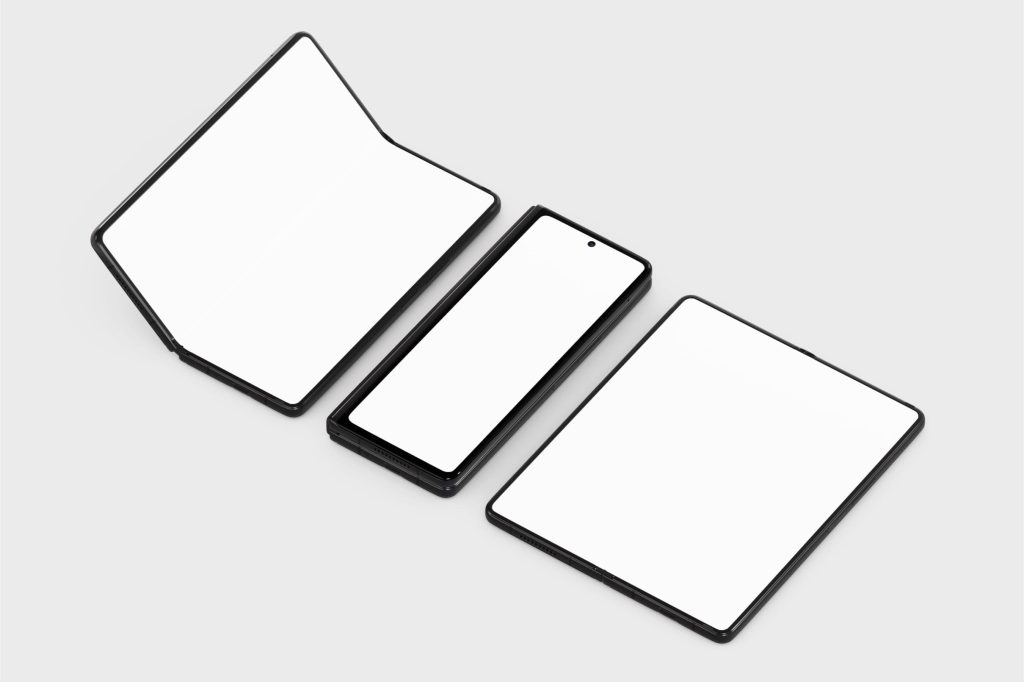

Our nanoporous silicon anode material brings winning battery performance to battery manufacturers worldwide. It overcomes the challenges of applying silicon in lithium-ion battery anodes. This is a big step towards helping everyone enjoy clean, electrically-powered mobility.

WE ARE TAMING SILICON

Better

Highly

compatible

Scalable

production

Advantages of our nanoporous silicon

Higher energy

density

Negligible anode

expansion

Low carbon

footprint

Large gains for consumers

Inhouse- production

cost efficient and scalable

Our nanoporous silicon is produced in our own, fully operational production facility near Amsterdam. The machinery covers 1200 square meters and operates at an industrial scale, can run 24/7 and is capable of producing up to 25 tons a year.

Efficient

Compatible

Scalable

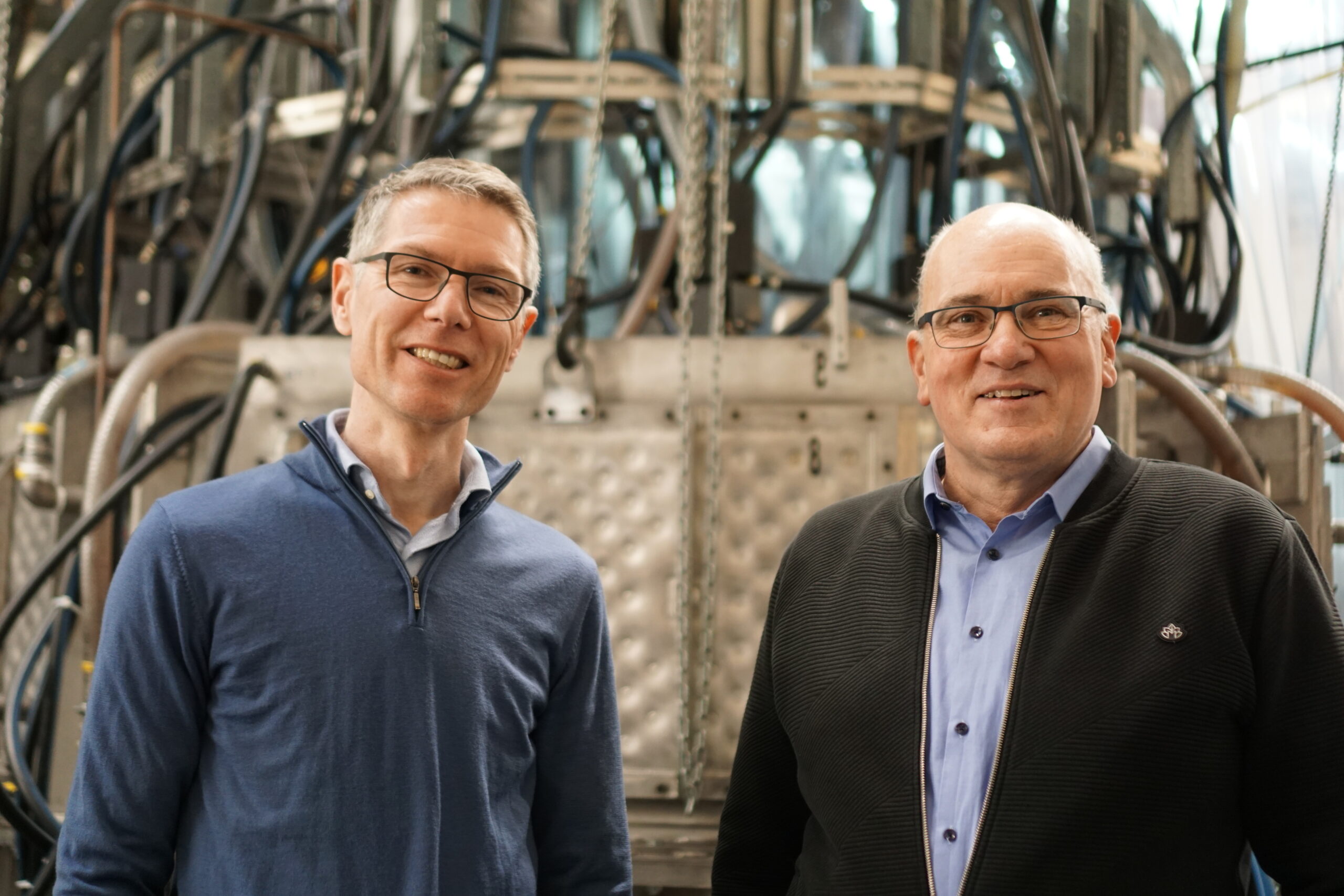

Mario Marinaro

Team Leader Batteries at ZSW

We have tested E-magy's silicon anodes and seen a negligible pouch cell thickness variation of <5% after 100 charging cycles, with an 80% wt silicon anode.

ZSW (Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg) is one of the leading institutes for applied research in battery technology.

Prof. Marnix Wagemaker

Head of Battery Research Group at Delft University of Technology

The porous silicon structure E-magy has developed mitigates the volume changes and addresses one of the biggest challenges to reach a long cycle life.

The TU Delft Battery Research Group supports developing safe and high performance energy storage in batteries worldwide.

Be part of our world class team

Are you interested in what we do? Want to be a part of a dynamic international team of scientists, specialists and engineers who are actively involved in helping to make the world a better place by mastering silicon for a cleaner automotive industry? Then don't hesitate to reach out. We're always interested in meeting more bright minds to join us.

Explore careers