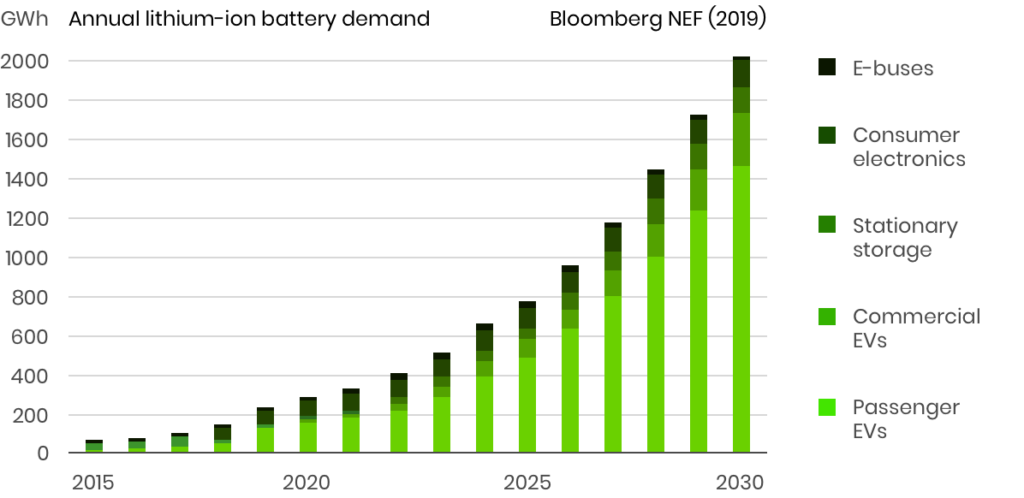

Demand for high energy batteries is on the rise

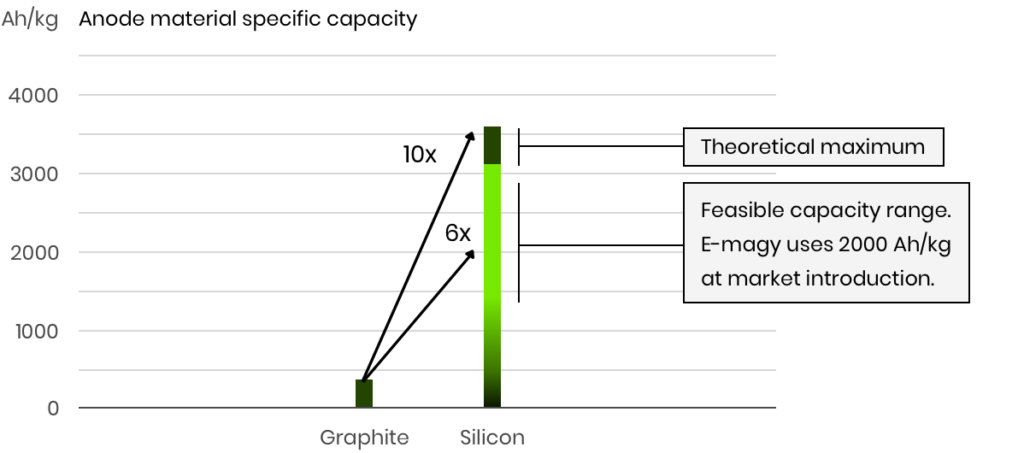

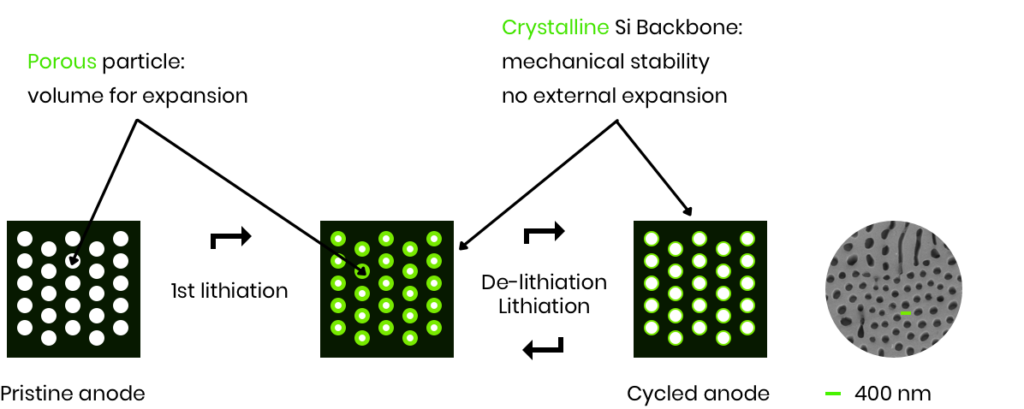

With climate change a key issue in the world today, electrification of mobility is rising fast. The demand for battery power is growing, but standing in the way of wide scale EV adoption are restricted range, charging speed and cost. We believe our specialty silicon has the answers.